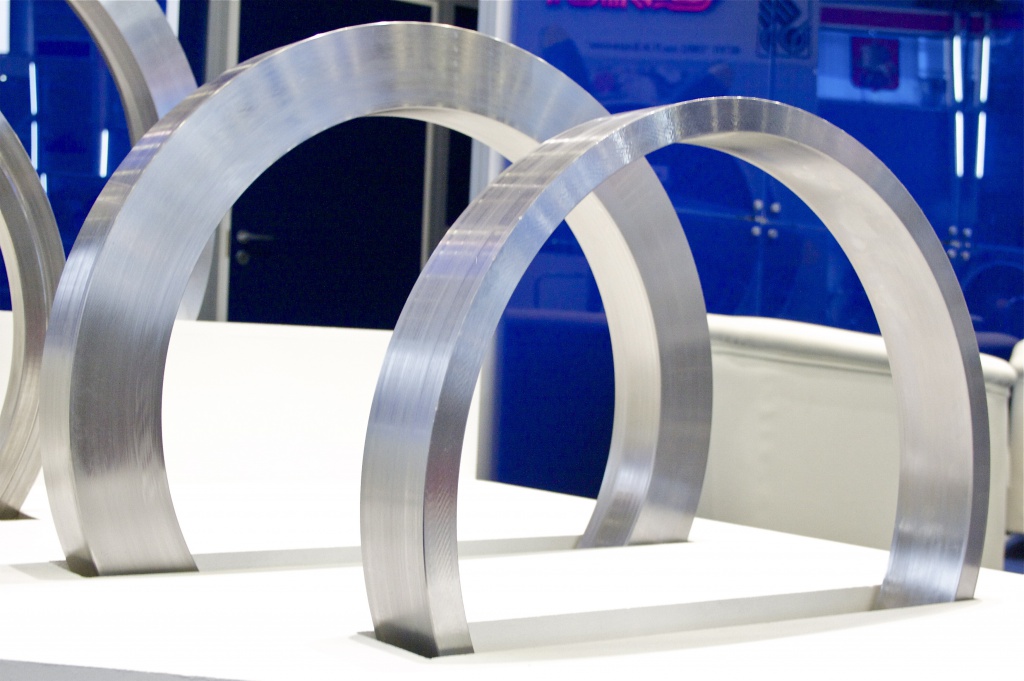

Distributing rings

Dimensions of the distributing rings produced:

- Outer diameter - 340-2000 mm

- Inner diameter - 200-1790 mm

- Height - 60-300 mm

- Weight of forging - 35-620 kg

Galion TH JSC offers cooperation in deliveries of distributing rings - forged and pressed, of simple and complicated profiles based on customer's drawings and requirements of OST1-90084-80, OST1-90396-81 from heatproof, stainless, constructional, carbon steel grades and titanium alloys. The rings are delivered in machined and non-machined condition, with full complex of control measures. If appropriate, the rings are delivered from FSUE (Federal State Unitary Enterprise) "Aviatekhpriemka."

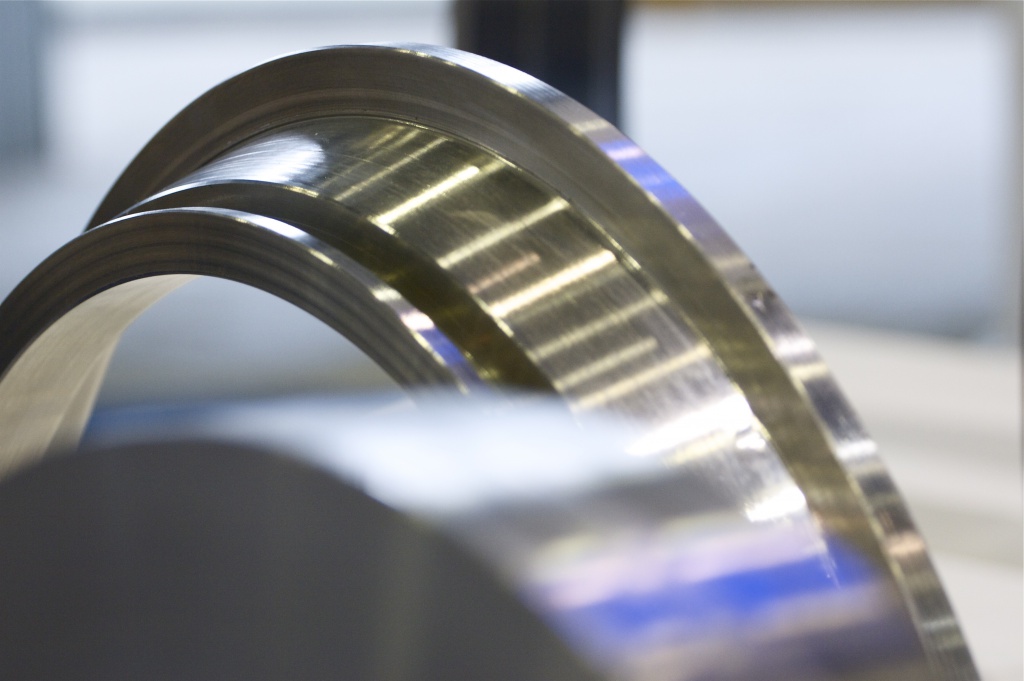

A unique technology of ring blank manufacture from corrosion- and heat resistant alloys was successfully developed in the plant. A forging press with 4000 ts tonnage capacity and ring reeling machine RAW 315/260 enable manufacture of up to 2000 mm diameter, up to 300 mm height, and up to 600 kg weight seamless-rolled rings from any deformable grades of steel or alloys..

Deliveries of ring blanks are carried out:

- in a "rough condition" with 6-10 mm tolerances per side;

- after initial machining;

- with fully completed parts, including final heat treatment, and all necessary types of testing

"Konstara" screw hydraulic presses with 1600 and 2500 ts tonnage capacity, a horizontal forging machine with 630 ts tonnage capacity enable producing hot pressworks of complicated structure with reduced overmeasure for machining, including turbine buckets and compressor blades.

Up to 10 kg weight of presswork products from carbon & alloyed steels and alloys. Linear dimensions up to 300 mm.

Quality of forging blanks including the mechanical property level is fully compliant with requirements of standards.

RU

RU